Kespet’s sheet metal claddings cover the entire pipeline system

Kespet’s quality sheet metal claddings are highly regarded in the industry, and it’s no wonder that we’ve worked hard to ensure they meet all the required specifications and are long-lasting, ready to install, and fully recyclable.

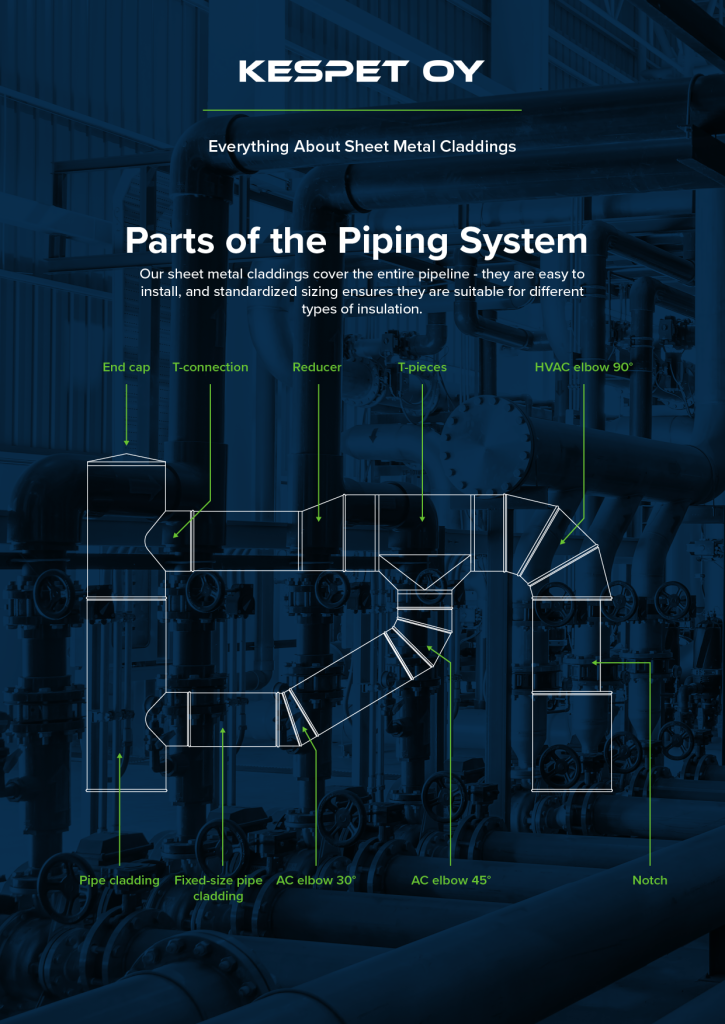

Our range of claddings covers the entire pipeline because we want to guarantee excellent cladding solutions for HVAC, AC, and process pipelines. In addition, standardized sizing ensures that the claddings are suitable for any insulation. So when you use Kespet claddings, you can be sure they will work with different types of insulation now and in the future.

Kespet’s range of sheet metal claddings includes:

- pipe claddings

- segment elbows for HVAC and process piping

- segment elbows for ventilation pipework

- formed pieces: reducers, t-connections, t-pieces, and end caps

- insulation boxes

- vessel claddings

- base structures.

Piping components and their characteristics

Let’s go through the components of our sheet metal cladding system and its main characteristics.

Reducer

The reducer is used as a modifier when the diameter of the cladding changes due to a change in the insulation and/or pipe. The standard non-centric cone is manufactured so that one side is straight – if required, it can also be manufactured to a specified line deviation.

The reducer is mounted at the larger end on a cladding joint lower beam and at the smaller end on a joint collar. On special request, we can make a bottom or top beam for both ends of the reducer.

T-connection

The t-connection is used as a starting collar from the larger or equal-sized pipe. In the standard model, the seam is on the long side, but we can also manufacture with the seam on the short side if required. The t-connection is also available as obliques, wherein the degree of the inner corner must be indicated on order.

Elbow and pipe cladding

These plumbing components were already familiar to us in the last part of this series, but let’s do a quick review anyway. Elbows are manufactured for both AC and HVAC pipes. The number of pieces for HVAC elbows varies according to the diameter of the sheet metal claddings, while for AC elbows, the number of pieces remains constant (a start piece, two intermediate pieces, and an end piece).

The standard lengths of the diaphragms are 1 000 and 1 250 mm. For diameters greater than 1 000 mm, the elbows and pipe claddings are made in two pieces.

End cap

As the name implies, the end cap is used where the pipe or insulation ends. The standard model is delivered as a two-piece, closed-end, but the end can also be manufactured with a hole to suit the pipe. On request, a one-piece end cap and a turned-edge end cap are also available, where the edge is turned over or under the cladding by approximately 20 mm.

Notch

The notch is used when the insulation has to be thinned for some obstacle in part of the pipe. In this case, the notch allows the obstacle to be bypassed. The notch can be manufactured as an open-ended version or a closed version. The closed version has a flap at the end, enabling a connection with a standard pipe cladding.

T-piece

A t-piece is a cladding coupling specially intended for larger ventilation ducts. The unified pipe exits the pipe in a conical shape. The T-piece is installed over the close brought claddings.

The T-piece is installed on top of the pipe cladding and can be manufactured without the cladding section.