A sheet metal cladding is the best choice you can make

Kespet manufactures high-quality, industry-recognized sheet paving that is second to none. Our claddings are quick and easy to install and stand the test of time and the elements without requiring maintenance. They also have a stylish look that never hurts.

Sheet metal claddings are also the safest protective cladding solution for fire safety, as the metal will not burn or release life-threatening fumes into the air. The products meet industry national and international standards. In case of fire, the sheet metal claddings protect the insulation products and slow the spread of fire.

The sheeting is also fully recyclable for metal recycling. If they are no longer needed but still have some years of use left, it is possible to reassemble and reinstall them in another location.

We manufacture segmental bends, special fittings, pipe casings, and fittings such as cones, t-joints, t-pieces, and end pieces for HVAC, AC, and process pipelines in our production facilities. Our products meet both national industry standards and building code requirements.

Sizing is everything

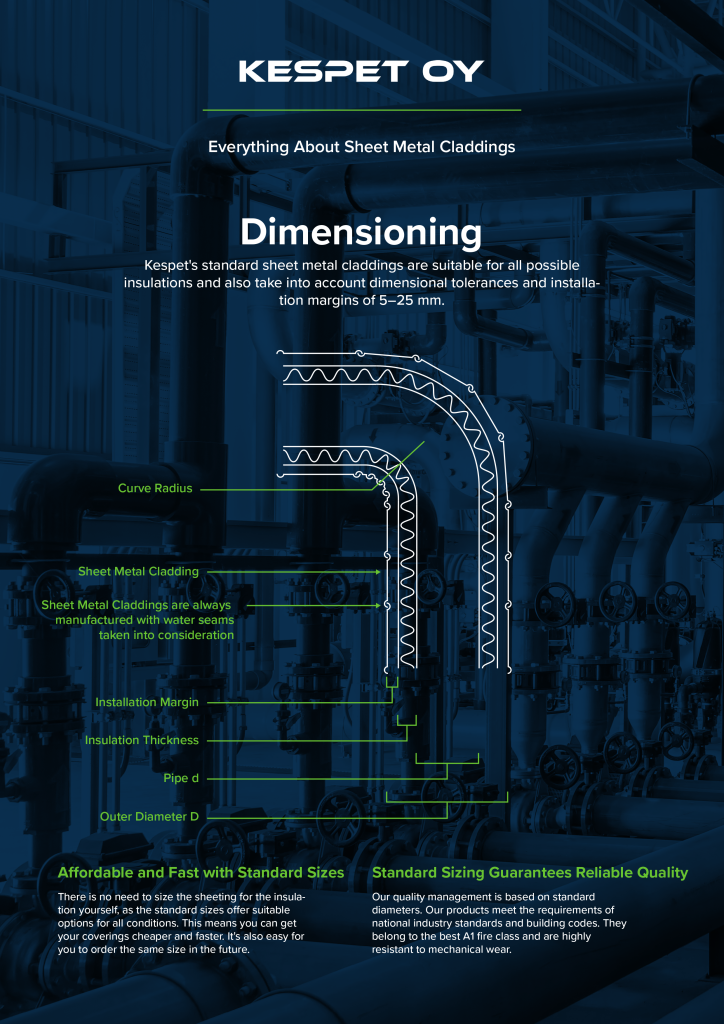

When dimensioning the claddings, it is crucial to consider the installation margin, which must be manageable. The sizing we design aims to ensure that the dimensions fit any insulation, from wool to cellular rubber. Therefore, if you use our claddings, you can be sure that they will work with different insulations in the future. On the other hand, when using different suppliers, you may come across incompatible diameters and beading types.

The diameters of our sheeting are selected to leave an average installation gap of 5-25 mm between the insulation and the sheeting. As far as possible, the cladding diameters are the same for different pipe size/insulation thickness combinations. Furthermore, the radii and piece sizes of the 1.5 x D segmental curves are optimized to be as close as possible to the required radius so that the insulation does not compress too much at the curve.

The standard sizes of our claddings allow us to have good quality control and high production and storage volumes. We have created a genuinely win-win concept with our sheet metal claddings, i.e., a concept that serves both the manufacturer and the customer.

Various insulation options have been taken into account in the design

Our sheeting range includes many standard products that are available off the shelf. This not only speeds up the delivery of the product but also reduces the price – there is no point in ordering sheet metal claddings to your own dimensions in the first place, but instead saves you time, effort, and money.

We have designed and implemented the claddings with all the most commonly used insulators in mind, making them compatible with all insulation materials. This also allows you to order new insulation for the same pipe size in five years. For example, it will still be suitable for the same claddings.

The products can also be manufactured to other national building codes and standards, depending on the customer’s needs. For example, we do a lot of projects for foreign clients who want to use their dimensions, which is also a good way for us to work.